Electrical Testing Requirements for Odour Control Equipment

Australian legislation includes strict requirements on electrical safety in the workplace. One important requirement to be aware of, is the need to ensure your air purification equipment is electrically tested and tagged in compliance with your states local legislation.

If you have odour control systems in your building, do not make the assumption that your supplier is meeting their legal obligations in this area! Every week we see companies which install leased/rented equipment and fail to ensure the equipment is tested & tagged as required. We have even seen machines that have been installed for almost a decade and the supplier has never tested & tagged the equipment. Other times they will tag the equipment with a ‘1 or 2 year’ renewal, despite legislation requiring 6 monthly intervals. Why do they do this? Because it’s less profitable to take the time and to employ appropriately qualified staff. If you are a Garbage Doctor® customer, you can be assured our technicians in all states include licensed electricians who electrically test & tag at every service, in compliance with local legislation. Our service intervals are based around meeting these requirements.

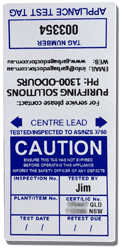

The good news is, that you can check your equipment at any time. A safety tag must be present on the rented/leased equipment on the power cord. It will look something like the image shown here with the date of testing and date of renewal.

What is Electrical Test & Tagging?

Electrical test and tagging is outlined in the AS/NZS 3760 standard, and applies to all electrical equipment, not just air purifiers. However, because air purification equipment is operating 24 hours a day, 7 days a week (and by nature they have moving parts which produce a small amount of vibration), this testing is very important. There is no need to take unnecessary risks by having a supplier with non-compliant electrical practices.

Although there are some variations on the requirements from state-to-state, the below can be used as a guide:

- All permanently installed lease/hire equipment must be test and tagged before installation and then every 6 months. This testing is the responsibility of the company you lease the equipment from.

- If you own your odour control system outright, then this testing must be done at least every 12 months. This is the responsibility of the person/company who owns the equipment.

(Note: whether you own or lease your Garbage Doctor® equipment, we test & tag for you at every service.)

Electrical test and tagging involves a series of tests on the equipment to ensure there is not a fault which could put people at risk around the equipment. This testing must be done by a competent or licensed person. Once the equipment has been tested, it must have a durable safety tag placed on the power cord. This tag needs to includes details of the person who carried out the testing, what the last testing date was, and when the equipment is next due for testing. A detailed log must also be kept of all past test results.

Fore more information on electrical safety in the workplace, we recommend viewing the ‘Safe Work Australia – Managing Electrical Risks in the Workplace‘ website, or for test and tagging requirements specific to your state, please refer to your states governing body.